Ningde City, Fujian Province

: +86-13958857568

: fdrbk.cn

:[email protected]

Multi-direction forging concept

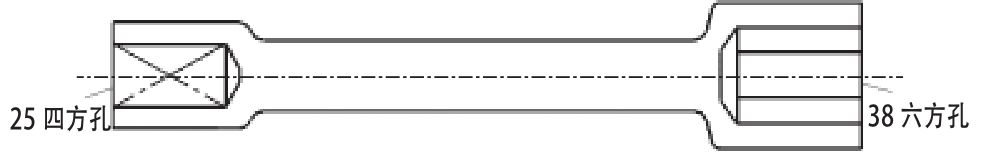

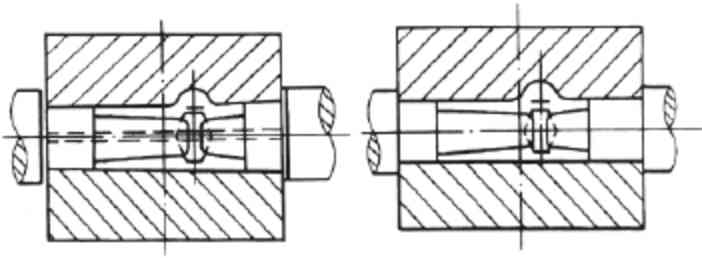

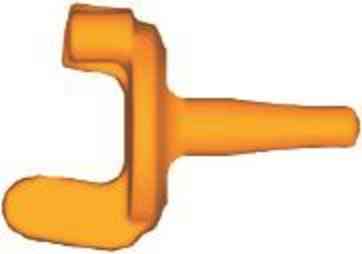

Multidirectional forging is a closed net forming forging process. It forging products, not only shape precision, but also extrude the product hole. Therefore, the forgings produced by this process have fine organizational structure, complex appearance and precision shape, and can also save materials and reduce energy consumption, especially in the processing of special-shaped inner hole products, and its advantages are more obvious. Precision forgings are shown in Figure 1.

Figure 1 Precision forging

Figure 2 Cylinder block of rock drill

The precision forgings in Figure 1 have irregular internal holes at both ends. When the multi-direction forging process is used to produce the product, the inside and outside of the product can be formed by one fire on the multi-direction forging equipment, and the production efficiency is several times higher than that of the original conventional forging process. There are two kinds of multi-direction forging process: one is to use special multi-direction forming die to achieve multi-direction forging on conventional forging equipment; The second is the use of multi-direction forging special equipment forging forming. The former uses conventional forging equipment, with a complex structure of the composite action mold to achieve multi-directional forging, its implementation tonnage is very limited, mostly used in the manufacture of small products, such as hardware miscellaneous parts. The individual weight of the products is less than one kilogram. The latter requires special multi-directional forging equipment, the initial investment is large, but the process performance is superior, the production mold is relatively simple, and the ability to adapt to the product is very high, the general product weight is about 10 kilograms, and the large equipment can even forge hundreds of kilograms of single weight forgings. The multi-way forging belongs to the latter category. Our company has two multi-direction forging production lines with 2000 tons of self-made hydraulic multi-direction forging machine as the main engine, and has forged and processed many kinds of forging parts such as rock drill cylinder block, machine head, automobile steering machine, universal coupling, valve body, and rotating rod joint.

Multidirectional forging process

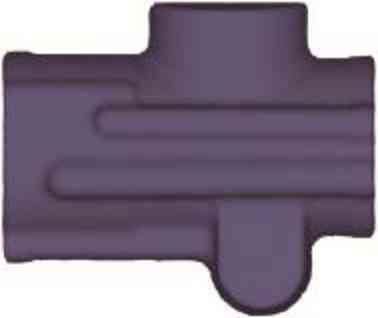

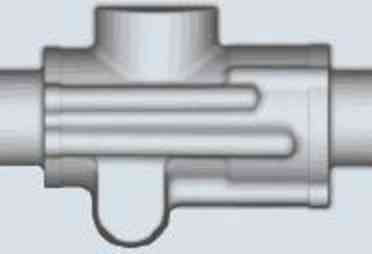

The product shape of rock drill cylinder body is shown in Figure 2. This product has both complex shape forging forming requirements, but also requires high strength thin-walled cylinder, is a very typical multi-direction forging products, common multi-direction forging specifications are mentioned in the lower sleeve mold structure

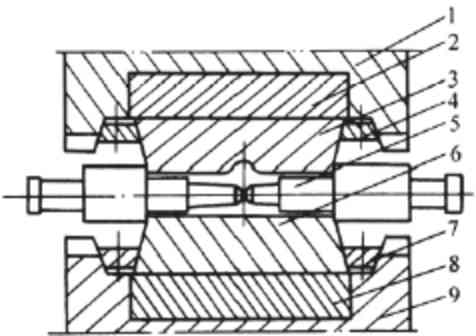

As shown in Figure 3, it is the rock drill cylinder.

Before we use multi-directional forging process to produce this product, the industry uses conventional forging process such as 3 tons die forging hammer processing. The appearance of cylinder body forgings processed by conventional forging process can still meet the quality requirements of product design. However, the conventional process can only forge solid body forgings. In the subsequent processing of accessories, it is necessary to first spend a lot of hours to hollow out the inner cavity, which consumes both materials and hours, and the production efficiency is very low. We use the multi-direction forging process to produce the rock drill cylinder, which not only has high appearance quality, but also realizes the closed forging without flash loss at the same time, because the pre-hole is squeezed out on both sides, which further greatly reduces the material consumption and also reduces the working time consumption of the later hole cutting. The multi-direction forging workpiece diagram is shown in Figure 4.

Figure 3 Structure of lower sleeve die

1- Upper die base 2- Upper support plate 3- Upper die 4- upper press plate 5- Punch 6- Lower die 7- Lower press plate 8- Lower support plate 9- lower die base

Figure 4 Multi-direction forging workpiece diagram

According to our actual calculation, the material consumption of the same specification products is 12 kg when using multi-directional forging, and 18 kg when using conventional forging process. Compared with the two processes, the conventional process consumes 50% more material than the multi-direction forging. It can be seen that multi-directional forging has quite obvious advantages in energy saving and consumption reduction.

Multi-directional forging not only saves material, but also cleverly saves energy. Still according to the above-mentioned rock drill cylinder forging as an example, the conventional process is 3 tons of die forging hammer forging, we use 2000 tons of hydraulic multi-direction forging machine forging. The multi-direction forging machine uses two side cylinders to exert forming energy, and the design tonnage of the cylinder is only 300 tons. If according to the general theoretical knowledge, the use of multi-direction forging process forging this product, the mold structure diagram is shown in Figure 5.

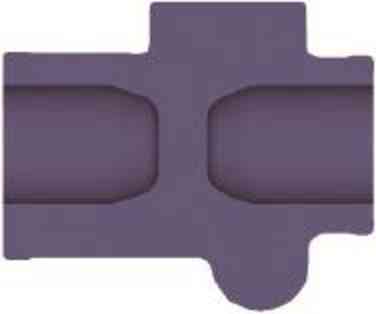

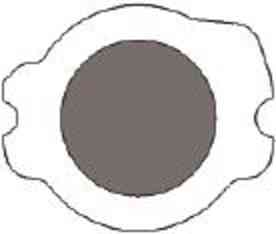

According to the mold structure, the cross section shape of the end punch is shown in Figure 6. From this figure, it can be obtained that the end punch area is about 130cm2, and the theoretical forming tonnage is 780 tons based on the product forming flow stress calculated at 600MPa. In the mold design, we make full use of the forming characteristics of the closed mold, and the punch shape is equivalent to the inner hole size of the forging, so as to effectively reduce the forming tonnage of the product. The structure of the improved die is shown in Figure 7, and the cross section of the improved punch is shown in Figure 8.

Figure 5 Mold structure diagram

Figure 6 Cross section shape of end punch

Figure 7 Improved mold structure

FIG. 8 Section of the improved punch

The shaded inner circle in Figure 8 is the improved punch section, with an area of only about 35cm2, and the required forming tonnage is only 210 tons according to the same forming flow stress. In addition to hollow forgings, for some forgings with complex shapes, multi-directional forging also has the advantages of simple process, high production efficiency and stable product quality. Multi-direction forging steering knuckle forging is shown in Figure 9.

To forge this product with traditional process, it is necessary to pass a relatively complex blank, and the final forging can be carried out after the initial forging step. Its production process occupies more equipment, uses more production personnel, and has a long production cycle. The use of multi-directional forging to manufacture the same product, without any pre-processing steps, the material is heated after direct molding, the process chain is short, the operator is less, the production cycle is short, and the so-called real fast and good province. The photo of multi-directional forging is shown in Figure 10.

As can be seen from the product picture, the forgings meet the requirements of net forming precision forging, less and no flash, in addition to having the advantages of the above process, compared with the conventional process forging can also save 10% to 15% of the flash material consumption.

Figure 9 Multi-direction forging steering knuckle forging

FIG. 10 Photos of multi-directional forging

Closing remarks

In recent years, the domestic multi-directional forging production has risen in many industries, especially in the national key projects have made outstanding achievements. However, there are still many application areas of multi-directional forging process to be developed. It is believed that in the near future, multi-directional forging will inevitably play a more excellent practical benefits.